Overview:

uis CenterRise M&C MeasuringIt .

and . It canThe system is suitable for all kinds of continuous casting machines such as square billet billet billetslabThe cT: on-site to desgin

: Multi-module acquisition chain, industrial Ethernet interface, high-speed embedded processing module

W: Real-time display of mold temperature field status, online analysis and prediction of mold breakout

Sr: Data exchange and storage management, reporting and printing system, with data analysis and self-learning functions

The Main technical parameters

Accuracy of temperature measurement: ±0.25℃

: Industrial Ethernet (TCP/IP),PROFIBUS-DP,CANopen

: DE0411 /1EC584/IEC1515

Transmission speed: 100M/bps

The composition of the software

breakout Offline query software for breakout Data recovery and self-learning software packages

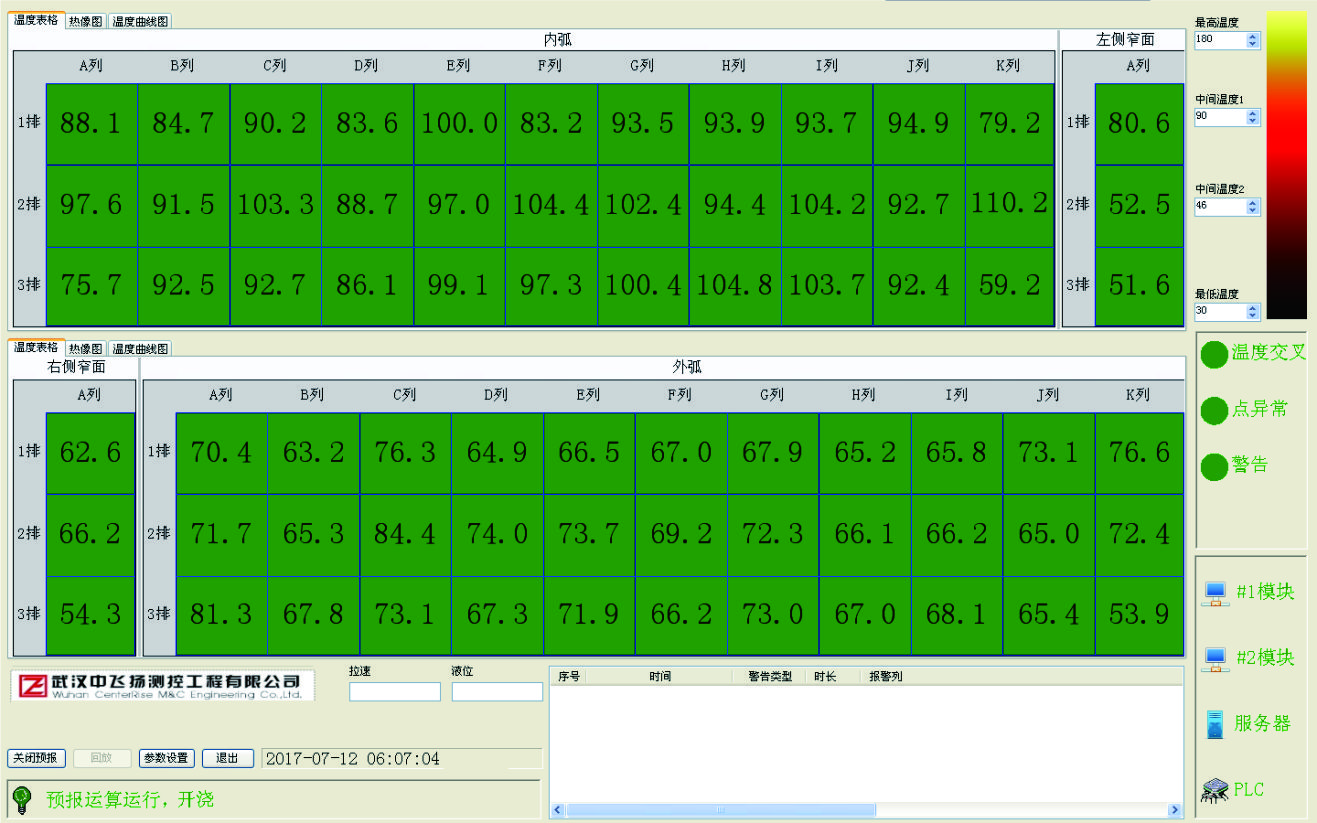

Data acquisition and monitoring software

The s of m

The functions of the system

Automatic selection of steel grade’sReal-time dynamic picture monitoring

Prediction alarm and information display of breakout signs

Automatic deceleration after alarm

Historical data storage and historical trend graph display

Automatic report generation and printing

Alarm prediction and pattern recognition of unknown steel grades by neural network

Dynamic real-time temperature profile prediction

MouldFIG 1:Typical process of mold breakout prediction

The features of the system

design ofand 2. The system has strong adaptability and can meet the transformation of various structural continuous .

. It 4. The combination of artificial neural network and intelligent forecasting model improves the alarm .

8. Can be seamlessly connected with MES-C220 mould expert system.

Wuhan CenterRise M&C Engineering CO., Ltd.

more info, please contact

Mobile: +86 13995588597

Wechat/whatsapp:+86 15727288019

sales@whzfy.com

Mention Arzooclassifiedads.club when calling seller to get a good deal

Bids