The automatic control foris very important to and improveThe molten steel is poured into the mold. In order to prevent overflow, the molten steel level must be kept stable. Otherwise, during the casting process, if castingof casting billet rfaceThe e surfaceif levelratecasting billet It means that casting billetThe principle of the system

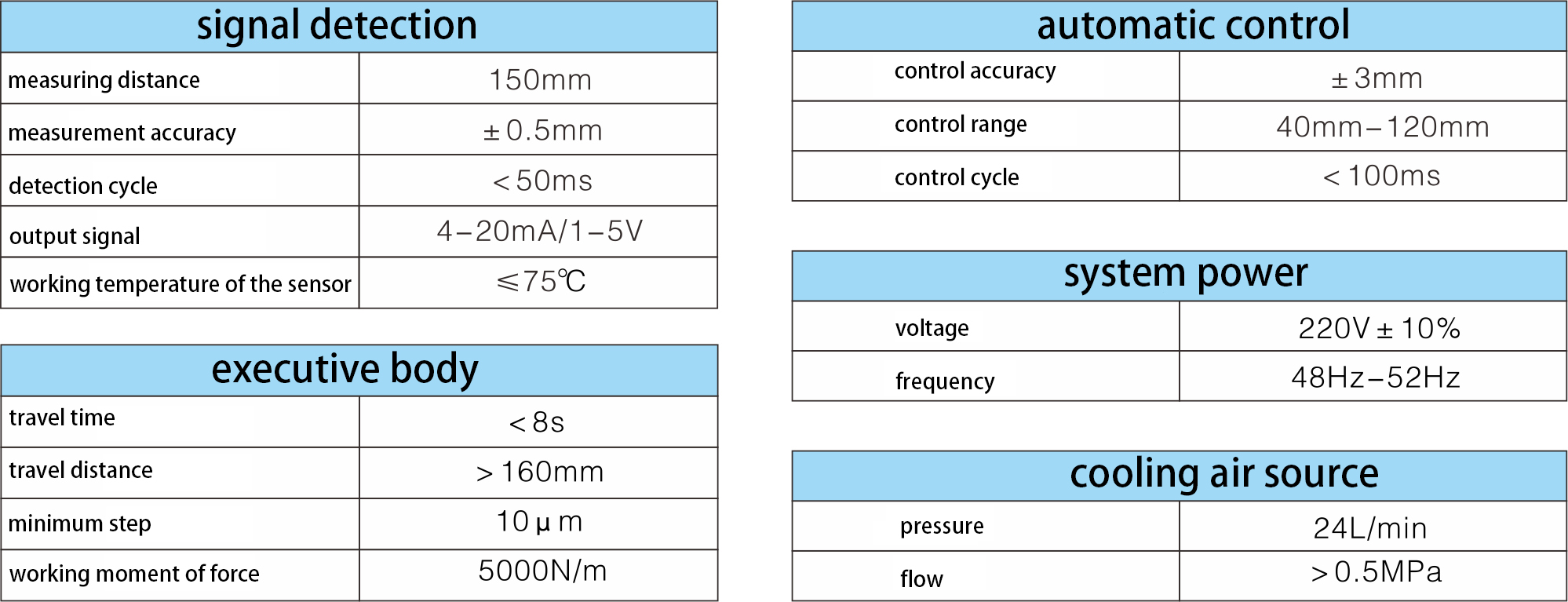

The etype The . Tlevel mold fluxcar The sensor is cooled by compressed air during use.

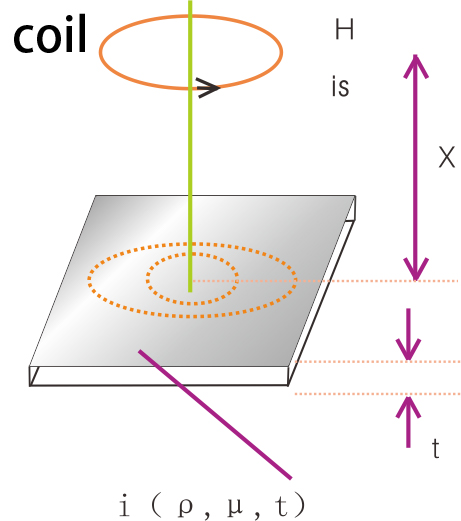

The principle is shown in the figure

A high-frequency exciting winding . The high-frequency magnetic field generated by the high-frequency ting winding induces eddy currents on the molten steel surface to form a magnetic field. Tmagnetic field generated by the induced eddy current ting windingting winding. winding levelwindingin.

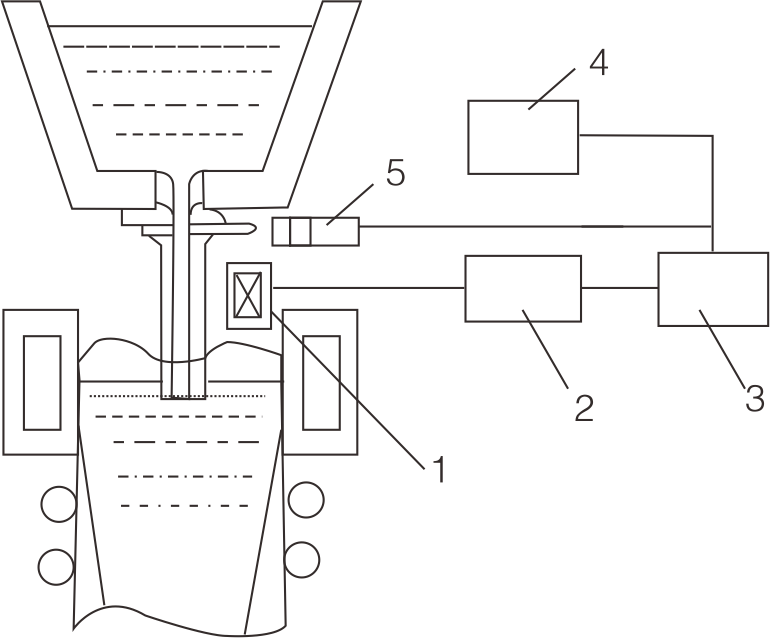

The detection end of the mold level automatic control system is ① eddy current displacement sensor, which uses the eddy current mutual inductance effect between the energized coil and the metal conductor to detect the distance. The effective signal of the eddy current sensor is amplified and linearized by the circuit of ② mold level gauge, which converts the 0-150mm change in the molten steel level of the mold into a standard signal of 4-20mA.DC, and then transmits it to the ③ control computer to complete data processing and system control functions. We can also control the actuator manually and automatically through the ④on-site operation display control panel, and the opening of the stopper is controlled by the ⑤ actuator to realize the automatic control of the molten steel level.

4 On-site operation display control panel;

5 digital actuator;

The control principle of the system

The system can be set to four control modes: automatic, semi-automatic, manual and motor clutch. The automatic mode is the closed-loop control system of the molten steel level, and control the opening of the stopper by the digital actuator; the semi-automatic mode uses opening degree setter and digital actuator to set the opening of the stopper manually; the manual mode is to open and close the button directly to control the opening of the stopper; the motor clutch mode is quickly changed from any of the above control methods to manual stopper operation.

The functions of the system also include: display and record of molten steel level, nozzle opening and casting speed; setting of molten steel level and nozzle opening; alarm of molten steel level at limit value etc.

In addition to taking the detection of molten steel level as the main feedback signal of the control system, the control system also considers various interference factors that have an impact on the level control. These interference factors include:

1. The influence of the change of the flow characteristics on the control system after the melt loss of the stopper

2. The influence of the weight change of molten steel in the tundish on the control system

3. The influence of the change of the casting speed of the continuous casting machine on the control system

4. The influence of the mold width change (the mold width is adjustable) on the control system

5. The influence of the vibration frequency and amplitude of the mold on the molten steel level gauge

The fIn order to overcome these disturbances, the mold. A. A of thechange compensation of casting speedcastingIn order to reduce the frequent action of the stopper, the system adopts the intergarting time change of the controller, and automatically selects a longer intergarting time when the molten steel level fluctuates light And the system will choose a shorter intergrating time when greatly. Igauge, which can overcomemold.

Wuhan CenterRise M&C Engineering CO., Ltd.

more ifo, please contact

Email: sales@whzfy.com

Wechat/whatsapp:+86 15727288019

Mention Arzooclassifiedads.club when calling seller to get a good deal

Bids